Magnetic Stirrer

for HAAGE High-Pressure Autoclaves

HAAGE stirring systems for autoclaves consist of high pressure stirrers without stuffing boxes. These stirring system possess integrated magnetic couplings in 6 sizes to transmit a maximum torque of 60 to 4000 Ncm. The magnetic stirring systems can be equipped with different stirring elements depending on your requirements.

HAAGE stirring systems for autoclaves consist of high pressure stirrers without stuffing boxes. These stirring system possess integrated magnetic couplings in 6 sizes to transmit a maximum torque of 60 to 4000 Ncm. The magnetic stirring systems can be equipped with different stirring elements depending on your requirements.

Magnetic Stirrer Models

Model |

Torque |

Ø Wave |

Rot. Speed |

PDR 6 |

60 |

10 |

0 - 2000 |

PDR 12 |

120 |

10 |

0 - 2000 |

PDR 18 |

180 |

10 |

0 - 2000 |

PDR 360 |

360 |

15 |

0 - 2000 |

PDR 720 |

720 |

20 |

0 - 1000 |

PDR 2000 |

2000 |

40 |

0 - 1000 |

| Technical Specifications | |

| Drive | direct current motor |

| Control system | progressive |

| Speed indicator | digital, in control cabinet |

| Max. pressure | 1000 bar |

| Max. temperature | 600°C on the inside of the autoclave |

| Sinks or inerting | gas connection (optional) |

The rotation speed details listed in the table are the default numbers. Depending on your requirements, a rotation speed of up to 3000 min-1 and torque of up to 4000 Ncm can be offered.

Upon request all mixers can be offered in accordance with the requirements of the ATEX regulations.

Stirring Elements

|

Mixing Gyro |

Propeller Stirrers |

Blade Stirrers |

Anchor Stirrers |

|

|

|||

Stirring duty: |

Suspend, Disperse, Liquid/liquid, Solid/liquid, Purge |

Homogenize, Disperse Liquid/liquid, Solid/liquid, |

Disperse Liquid/liquid, |

Heat exchange, Mixing |

Viscosity range: |

20 PAs |

10 PAs |

10 PAs |

2 - 10 PAs |

Flow section: |

3 |

turbulent |

turbulent |

transition-turbulent |

Performance indicators Ne: |

|

0,35 - 0,85 |

4,6 |

0,2 - 2,0 |

Direction of primary flow: |

radial-tangential |

axial-radial |

radial |

tangential |

The rotational range of the stirrers has to be adapted depending on the stirring element

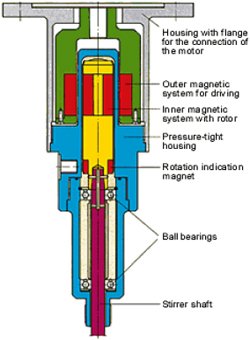

Structure of the Stirrer Systems

The high-pressure stirrers consist of an inner and outer subsystem.

The inner subsystem of the agitator is mounted to the autoclave in a tightly screwed, statically sealed pressure-resistant housing. It includes the internal magnet of the magnetic coupling as well as the agitator shaft, with several bearings for a smooth and vibration-free running. When worn down, these bearings can be replaced easily.

The external subsystem of the agitator consists of the outer aluminum stirring housing with a built-in magnet. Additionally, a stirring motor is directly coupled to the magnet.

The force of the stirring motor is transmitted contact-free via the outer magnet to the inner magnet.

With this construction, none of the rotating parts have to be sealed against the operating pressure in the autoclave. This design principle permits high speeds in high pressure ranges with no need for additional seals. All pressure-loaded parts of the stirring system that come into contact with the medium are made of the same material as the autoclave vessels. As a measure of protection against a chemical attack the inner magnet is equipped with a welded gas-tight case. To protect the lower bearings the stirrers are equipped with a cooling jacket.

All rights to technical modifications reserved.